|

AMT&C NINGBO,LLC

|

Rare Earth Lifting Magnets

| Price: | 10.0~1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Lifting Electromagnet adopts a special design magnetic circuit which has large air space and magnetism density.

General Description

AMT&C Lifting Electromagnet currently operates from the largest production lines to the smallest job shops and provides the same safety, high performance, and low operating cost for each user. For cast ingots, steel balls and various kinds of steel scraps, our product is all suitable.

Work Theory

Here we take scrap steel for example. A Lifting electromagnet can be used for moving scrap steel from one place to another. In a scrapyard, a crane has a large iron disc that is not a permanent magnet. The crane operator lowers the electromagnet into a pile of scrap steel and then switches on the electricity. This causes the steel disc to become a powerful magnet. Scrap steel is attracted to the disc. When the operator switches off the electricity, the scrap steel falls off the disc. In this way, large amounts of scrap steel can be moved easily from one place to another.

Character

1. Lifting Electromagnet adopts a special design magnetic circuit which has large air space and magnetism density. It is made of aluminum wire and the coil protection plate is made of the rolled high Mn steel plate that has good performance of wear-resistance & heat-proof. It also has the characteristics of light weight, low power consumption, high lifting capacity and long serving life. 2.Lifting Electromagnet has fine insulation structure.The insulation treatments adopt the vacuum trying&glue filling,which has improved the electrical and mechanical performance of the coils. 3. Lifting Electromagnet generally adopts the control mode of constant voltage. It can further improve the lifting capacity if changing to adopt the control model of over excitation.

Specification

AMT&C Lifting Electromagnet currently operates from the largest production lines to the smallest job shops and provides the same safety, high performance, and low operating cost for each user. For cast ingots, steel balls and various kinds of steel scraps, our product is all suitable.

Work Theory

Here we take scrap steel for example. A Lifting electromagnet can be used for moving scrap steel from one place to another. In a scrapyard, a crane has a large iron disc that is not a permanent magnet. The crane operator lowers the electromagnet into a pile of scrap steel and then switches on the electricity. This causes the steel disc to become a powerful magnet. Scrap steel is attracted to the disc. When the operator switches off the electricity, the scrap steel falls off the disc. In this way, large amounts of scrap steel can be moved easily from one place to another.

Character

1. Lifting Electromagnet adopts a special design magnetic circuit which has large air space and magnetism density. It is made of aluminum wire and the coil protection plate is made of the rolled high Mn steel plate that has good performance of wear-resistance & heat-proof. It also has the characteristics of light weight, low power consumption, high lifting capacity and long serving life. 2.Lifting Electromagnet has fine insulation structure.The insulation treatments adopt the vacuum trying&glue filling,which has improved the electrical and mechanical performance of the coils. 3. Lifting Electromagnet generally adopts the control mode of constant voltage. It can further improve the lifting capacity if changing to adopt the control model of over excitation.

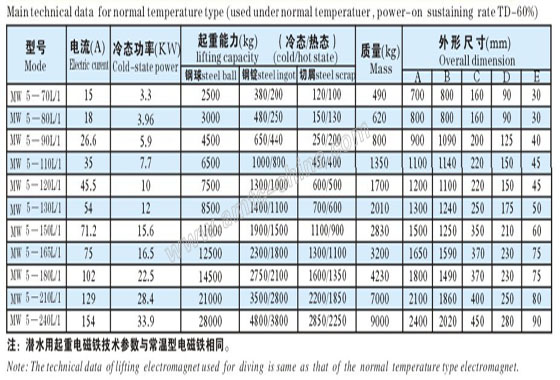

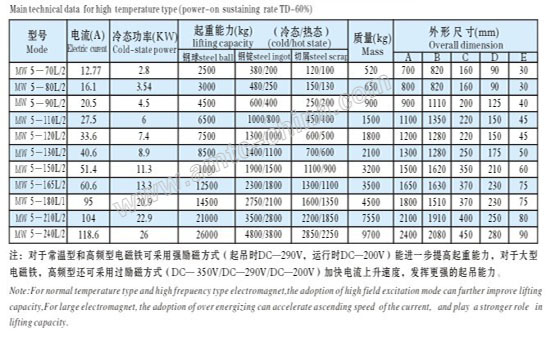

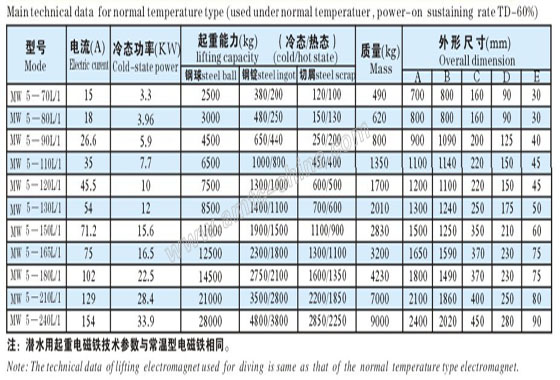

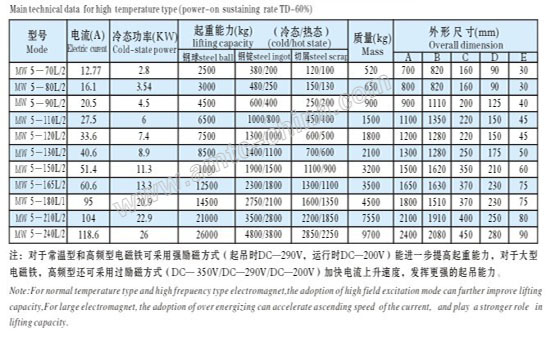

Specification

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Rare Earth Disc Magnets

Rare Earth Magnets Disc

Rare Earth Magnets Sphere

Rare Earth Magnets Epoxy

Rare Earth

Rare Earth Magnet

More>>

.jpg)