|

AMT&C NINGBO,LLC

|

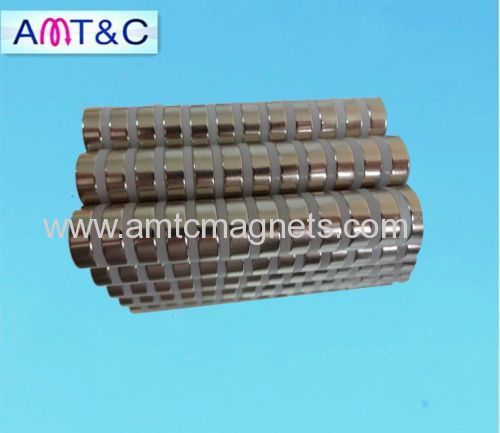

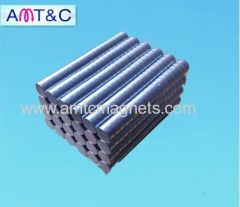

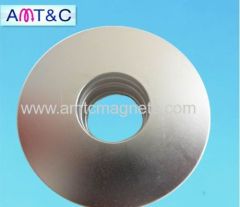

Neodymium (NdFeb) Disc magnet Ni coating

| Price: | 1.0~100.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Grade:N33

Disc Size: D13(+0/-0.1) x h3(+0/-0.1)

Magnetization direction: Axial

Br>1,13 T; Hcb>836 kA/m; Hcj>955 kA/m; (BH)max>245 kJ/m3; Tw<80 C

General Description:

Neodymium magnets offer higher energy density than all other permanent magnets. As the strip casting and HD process were used in our factory , we developed high corrosion resistant grade that give superior weight loss test results,some grade even less than 1.5mg/cm2 in HAST test. Most of these magnets are used in motor ,generator. The size ,shape and coating can be figured out according to customer's requirement.

Surface Treatment Method:

Magnet disc

Neodymium magnets offer higher energy density than all other permanent magnets. As the strip casting and HD process were used in our factory , we developed high corrosion resistant grade that give superior weight loss test results,some grade even less than 1.5mg/cm2 in HAST test. Most of these magnets are used in motor ,generator. The size ,shape and coating can be figured out according to customer's requirement.

Surface Treatment Method:

| Type | Information |

| Metallic | Zinc,Nickel,Nickel+Nickel,Copper+Nickel,Nickel+Copper+Nickel,Gold |

| Organic | Epoxy,Nickel+Epoxy coating |

| Temporary | Surface Pssivation |

Magnet disc

2. Technology: Utilizes new Sintered NdFeB magnet techniques and equipment such as strip casting, HDDR technology;

3. Magnetic properties: High coercive force, the max operation temp is up to 200 degree centigrade or 380 curie temperature;

4. Grades: N33-N52,33M-48M,33H-48H,30SH-45SH,30UH-38UH and 30EH-35EH;

5. Shapes and sizes: Various kinds or according to customers' request;

6. Coatings: Ni, Zn, gold, copper, epoxy, chemical, parylene and so on;

7. Certification:ISO9001:2008 and ISO/TS16949:2009.

8. Applications of the Disc magnet: Widely used in different applications, such as sensors, motors, rotors, wind turbines/wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Neodymium Magnet Disc

Coating Ndfeb Magnet

Disc Ndfeb Magnet

Sintered Ndfeb Magnet Disc

Neodymium Ndfeb

Neodymium Disc

More>>