|

AMT&C NINGBO,LLC

|

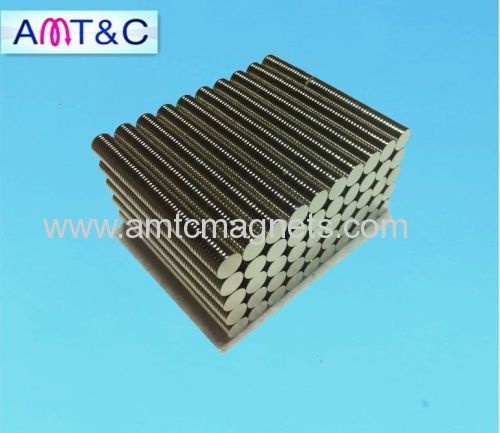

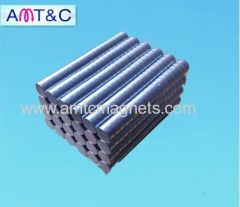

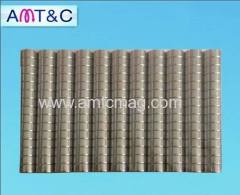

Neodymiummagnet (NdFeb) Disc D9.8(+0/-0.1) x h4 (+0/-0.1)

| Price: | 1.0~100.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Grade: N33

Size: D9,8(+0/-0.1) x h 4 (+0/-0.1)

Magnetized axial

Ni coating

General narration:

Neodymium magnet (also known as NdFeB, NIB, or Neo magnet), is a most widely-used type of rare-earth magnet, and a permanent magnet made from an alloy of neodymiumm, ironn, and boron to form the Nd2Fe14B tetragonal crystalline structure. It was developed in 1982. Neodymium magnets are the strongest type of permanent magnet made. They have replaced other types of magnets in the many applications in modern products that require strong permanent magnets, such as motors in cordless tools, hard disk drives, and magnetic fasteners. Because neodymium magnet have greater strength which allows the use of smaller, lighter magnets for a given application.

Neodymium magnet (also known as NdFeB, NIB, or Neo magnet), is a most widely-used type of rare-earth magnet, and a permanent magnet made from an alloy of neodymiumm, ironn, and boron to form the Nd2Fe14B tetragonal crystalline structure. It was developed in 1982. Neodymium magnets are the strongest type of permanent magnet made. They have replaced other types of magnets in the many applications in modern products that require strong permanent magnets, such as motors in cordless tools, hard disk drives, and magnetic fasteners. Because neodymium magnet have greater strength which allows the use of smaller, lighter magnets for a given application.

| For examples: Head actuators for computer hard disks; Magnetic resonance imaging; Magnetic guitar pickups; Loudspeaker and headphones; Electric motors; Spindle and stepper motors; Drive motors for actuators; Electric generators for wind turbines. |

Neodymium magnet is an iron based permanent magnet, because of this, it is easy to be rusted or oxidation. To avoid such problems, the magnet coating, electrical plating or suitable surface treatment are needed.

Magnet disc

| Available Coatings for Magnets | ||||

| Surface | Coating | Thickness (Microns) | Color | Resistance |

| Passivation | 1 | Silver Grey | Temporary Protection | |

| Nickel | Ni+Ni | 10-20 | Bright Silver | Excellent Against Humidity |

| Ni+Cu+Ni | ||||

| Zinc | Zn | 8-20 | Bright Blue | Good Against Salt Spray |

| C-Zn | Shinny Color | Excellent Against Salt Spray | ||

| Tin | Ni+Cu+Sn | 15-20 | Silver | Superior Against Humidity |

| Silver | Ni+Cu+Ag | 10-20 | Silver | Superior Against Humidity |

| Gold | Ni+Cu+Au | 10-20 | Gold | Superior Against Humidity |

| Copper | Ni+Cu | 10-20 | Gold | Temporary Protection |

| Epoxy | Epoxy | 15-25 | Black,Red,Grey | Excellent Against Humidity&Salt Spray |

| Ni+Cu+Epoxy | ||||

| Zn+Epoxy | ||||

| Parylene | Parylene | 5-20 | Grey | Excellent Against Humidity,Salt Spray,Superior Against Solvents,Gases, Fungi and Bacteria,FDA Approved |

| Chemical | Ni | 10-20 | Silver Grey | Excellent Against Humidity |

Magnet disc

2. Technology: Utilizes new Sintered NdFeB magnet techniques and equipment such as strip casting, HDDR technology;

3. Magnetic properties: High coercive force, the max operation temp is up to 200 degree centigrade or 380 curie temperature;

4. Grades: N33-N52,33M-48M,33H-48H,30SH-45SH,30UH-38UH and 30EH-35EH;

5. Shapes and sizes: Various kinds or according to customers' request;

6. Coatings: Ni, Zn, gold, copper, epoxy, chemical, parylene and so on;

7. Certification:ISO9001:2008 and ISO/TS16949:2009.

8. Applications of the Disc magnet: Widely used in different applications, such as sensors, motors, rotors, wind turbines/wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!