|

AMT&C NINGBO,LLC

|

The magnificent quality of neodymium magnets

| Price: | 0.5~5.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

the excellent quality and miscellaneous Neodymium magnets are laid in my corporation.

The demonstration:

Rare earth Neodymium magnets (NdFeB) have been available for industrial use since 1984. Neo magnets have extremely high magnetic energy and therefore are used in applications which require high powered magnets, as well as applications where size and weight reduction are of interest or need to be considered. These qualities have made NdFeb magnets preferable over the commonly used larger and less powerful Ferrite magnets.

The main raw materials NdFeB permanent magnets are rare earth metal-Neodymium (Nd) 32%,metal element Iron (Fe) 64% and nonmetal element Boron(B) 1% , and some small amount added Dysprosium (Dy), Terbium(Tb), Cobalt (Co), Niobium(Nb),Gallium (Ga),Aluminum (Al),Copper (Cu) and other elements. Ternary system neodymium permanent materials are of Nd2Fe14B compound as a matrix, its compositions should be similar with the molecular formula of compound Nd2Fe14B, but, when it is proportioning according to the composition of Nd2Fe14B compound, the magnet performances are very low, and even without magnetic, just on the actual magnets, when the content of neodymium and boron are more than on Nd2Fe14B compound, we can get the better permanent magnet performances.

Neodymium magnets can be divided into three main groups:

1.Regular Neodymium

2.High corrosion resistant Neodymium

3.Bonded Neodymium (Isotropic): Manufactured by the injection of plastic material and Neodymium into a mold. This production method yields a very precise magnet which does not require further grinding and does not suffer substantial current loss.

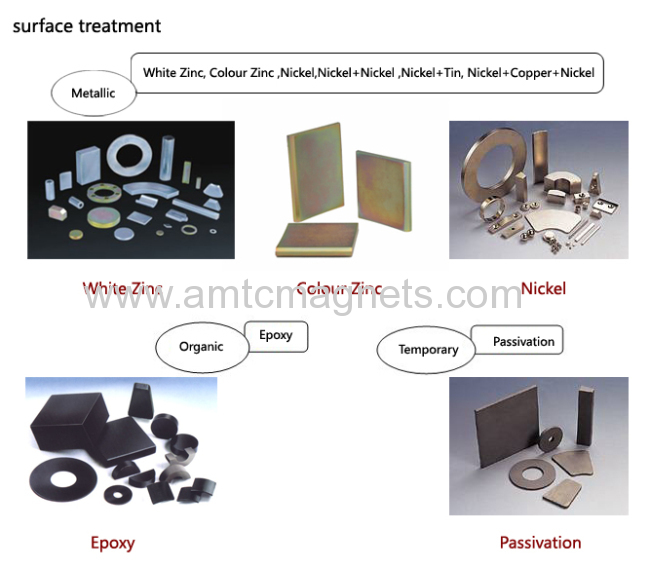

Neo magnets are known for their high temperature resistance, making them durable and functional in temperatures exceeding 200°C. This quality makes them ideal for heavy industry applications. Sintered Neodymium, however, is sensitive to oxidization and can develop corrosion, so magnets are usually coated with Nickel+Copper+Nickel,Nickel+Sn, Zn(galvanization), Epoxy and Passivation for their protection.

Rare earth Neodymium magnets (NdFeB) have been available for industrial use since 1984. Neo magnets have extremely high magnetic energy and therefore are used in applications which require high powered magnets, as well as applications where size and weight reduction are of interest or need to be considered. These qualities have made NdFeb magnets preferable over the commonly used larger and less powerful Ferrite magnets.

The main raw materials NdFeB permanent magnets are rare earth metal-Neodymium (Nd) 32%,metal element Iron (Fe) 64% and nonmetal element Boron(B) 1% , and some small amount added Dysprosium (Dy), Terbium(Tb), Cobalt (Co), Niobium(Nb),Gallium (Ga),Aluminum (Al),Copper (Cu) and other elements. Ternary system neodymium permanent materials are of Nd2Fe14B compound as a matrix, its compositions should be similar with the molecular formula of compound Nd2Fe14B, but, when it is proportioning according to the composition of Nd2Fe14B compound, the magnet performances are very low, and even without magnetic, just on the actual magnets, when the content of neodymium and boron are more than on Nd2Fe14B compound, we can get the better permanent magnet performances.

Neodymium magnets can be divided into three main groups:

1.Regular Neodymium

2.High corrosion resistant Neodymium

3.Bonded Neodymium (Isotropic): Manufactured by the injection of plastic material and Neodymium into a mold. This production method yields a very precise magnet which does not require further grinding and does not suffer substantial current loss.

Neo magnets are known for their high temperature resistance, making them durable and functional in temperatures exceeding 200°C. This quality makes them ideal for heavy industry applications. Sintered Neodymium, however, is sensitive to oxidization and can develop corrosion, so magnets are usually coated with Nickel+Copper+Nickel,Nickel+Sn, Zn(galvanization), Epoxy and Passivation for their protection.

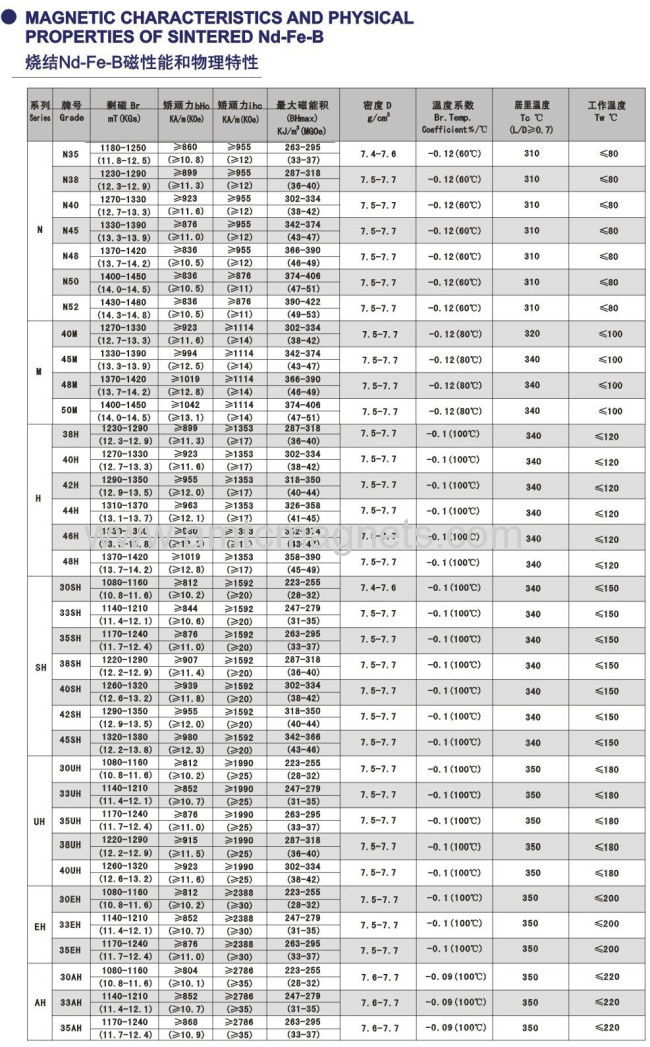

Material charateristics of NdFeB magnet products

Item | Inspecting method | Inspecting standard | |

Magnetic performance | GB/T 13560-2000 | GB/T3217-92 | |

Weightlessness rate | Test cases with constant temperature & constant pressure ,96hrs , (130±2℃(0.27MPa) | Normal products :≤50mg/cm2 ; Low weight-loss products :≤10mg/cm2 | |

Density | Drainage method for measuring | 7.4-7.6g/ cm3 | |

ROHS requirements | Equivalent to use the green purchasing standards CS-K1100 (2 edition) in SANYO | ||

Mechanical performance index | Hardness: 570HV | Fracture toughness :2.5-5 Mpam2 | |

Resistivity:150μΩ·cm | Specific heat:0.502 Kj· (kg·℃ | ||

Compressive strength:780 N/mm2 | Thermal conductivity :8.9551 w/m·K | ||

Bending strength :290 Mpa | Thermal expantion coefficient(in vertical orientation direction): -4.8X10-6K | ||

Advantages and Disadvantages of NdFeB Permanent Magnets

1) Is the strongest magnetic of permanent magnets, has the high energy (BH value) and good coercive force. |

2) Manufacturing by the the vacuum sintering process, process maturity;small dimensions,have the good performances and prices; energy (BH value) of NdFeB magnets is more than ten times higher than Ferrites, it is the strongest magnetic materials in the world today, have "magnetic king"reputation. |

3) Using the cutting process after sintering,according to the requirements,by the rapid processing, they can be cutted into square,disc.,ring,segment(like tile shape),and so on;Dimension tolerance is commonly +/-0.05mm,if special request,it can be controlled within 0.05mm range by increasing grinding; If requesting the higher process,using the fast quenching scales manufacturing Nd-Fe-B binding NdFeB1988,the precision of dimensions can be reached 0.01mm,but because the organic binder content cause the low energy product,and the much higher cost of forming dies. |

4) NdFeB permanent magnets are easy to be rusted/oxided, so their surface should be done eletroplating treatment, such as galvanized(Zn coating), Nickel+copper+nickel, and so on, generally, it requests more than 48hours in Salt-spray test; also can be passivated treament to slow down its oxidative speed; if using the vacuum plating aluminum + electrophoresis epoxy resin, it can go through more than 96hours in Salt-spray condition. |

Basic Performance Comparison Table of Permanent Magnets

Magnets | BHmax(MGOe) | Max.Working Temp.(0C) | Corrosion Resistance | Magnetic Performance | Material Price | Coercive Force | Processing Charateristics | Composite Index |

26-52 | ≤200 | C | A+ | B- | A+ | B+ | 70 | |

SmCo 2:17 | 22-30 | ≤300 | A | A | C- | A | C | 64 |

SmCo 1: 5 | 16-25 | ≤250 | A | A- | C | A- | C | 62 |

Bonded NdFeB | 5/12 | <150 | B- | B | C | A+ | - | 68 |

AlNiCo | <10 | <550 | A+ | B | B | C- | C | 54 |

3-4.5 | < 350 | A | C | A | B- | B | 64 | |

2-3 | < 150 | A | C | B | B- | - | 66 | |

Rubber | 0.7/1.6 | <85 | B | C | B+ | C | A | 56 |

NdFeb magnets can be used for a wide variety of applications:

•Electronics – Sensors, hard disk drives, sophisticated switches, electro-mechanical devices etc.

•Auto Industry – DC motors (hybrid and electric), small high-performance motors, power steering.

•Medical – MRI equipment and scanners.

•Clean Tech Energy – Water flow enhancement, wind turbines.

•Magnetic Separators – Used for recycling, food and liquids QC, waste removal.

•Magnetic Bearing – Used for highly sensitive and delicate procedures in various heavy industries.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Magnets Neodymium

Cylinder Neodymium Magnets

Disc Neodymium Magnets

Neodymium Disc Magnets

Neodymium Magnets Block

Neodymium Motor Magnets

More>>